No power needed: passive cooling technologies tested at WIWeBWehrwissenschaftliches Institut für Werk- und Betriebsstoffe

Equipment, Information Technology and In-Service Support- Date:

- Place:

- Erding

- Reading time:

- 3 MIN

Being exposed to extremely high temperatures in theaters of operation can take its toll on stored equipment. However, it is not always possible to use energy-hungry devices for cooling. The Bundeswehr Research Institute for Materials, Fuels and Lubricants (WIWeBWehrwissenschaftliches Institut für Werk- und Betriebsstoffe) in Erding, Bavaria, recently tested various passive cooling technologies.

Shading is a proven passive cooling method that was compared with new technologies during testing

Bundeswehr/Maria AignerSupported by the Bundeswehr Technical Center for Land-Based Vehicle Systems, Engineer and General Field Equipment (WTDWehrtechnische Dienststelle 41) in Trier, the Bundeswehr Technical Center for Protective and Special Technologies (WTDWehrtechnische Dienststelle 52) in Oberjettenberg and other Bundeswehr agencies, WIWeBWehrwissenschaftliches Institut für Werk- und Betriebsstoffe employees closely examined various passive cooling technologies. Companies from the business sector were also involved in the project. The tests were conducted in the open air as well as in a laboratory and under a solar simulator.

The tests focused on different cooling coating systems which were to be evaluated in comparison with other passive cooling technologies.

The experts used containers coated with standard Bundeswehr paints without cooling effect as their starting point. Some of the containers then were – quite conservatively – shaded with a roof or a camouflage net.

This traditional approach was compared with new technologies such as special cooling coatings or the installation of temperature-reducing elements that slow down the warming of the containers considerably.

In order to better compare the effectiveness of the different cooling technologies, the power consumption of the air conditioners installed in the different test containers was used as a reference point. The power consumption of air conditioners in uncoated containers was simply compared with the power consumption of those installed in containers with a new coating or with plates attached. The use of passive cooling techniques improved cooling and resulted in a significantly lower power consumption of the air conditioning units.

During the tests, the temperature was measured at various points, both inside the containers and on their outer surface.

On a sunny day with an outside temperature of almost 33 degrees Celsius, for example, the surface temperature of a bronze green reference container was 60 degrees Celsius, while its inside temperature climbed as high as 38 to 40 degrees. A sandy beige reference container still heated up to 50 degrees on the outside. On the inside, however, the thermometer hit 36 to 38 degrees.

Most of the cooling technologies tested ensured surface temperatures of between 35 and 40 degrees Celsius. In comparison, using a coating technology based on passive radiation cooling resulted in surface temperatures of around 30 degrees Celsius, which was even below the air temperature measured. This striking effect is achieved by reflection of the visible light and heat emission in the infrared frequency range.

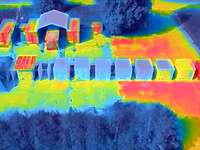

View of the test environment at WIWeBWehrwissenschaftliches Institut für Werk- und Betriebsstoffe from above

Bundeswehr/Michael Kopa

The infrared image shows the effect of the cooling coatings

Bundeswehr/Michael KopaThe tests concerning the heat buildup inside the containers showed similar results: In containers with a novel coating and additional temperature-reducing elements, temperatures remained below the 30 degrees mark. The other technologies like shading also ensured that the temperatures inside the containers only climbed as high as 31 to 33 degrees.

All techniques tested showed a cooling effect. Depending on the technology, however, there are different advantages and disadvantages related to a potential use within the Bundeswehr. The coatings’ camouflage effect, for example, is not yet ideal. That is why the coatings would still have to be combined with camouflage nets or other camouflage methods at the moment.

The test results and the conclusions regarding the different cooling techniques’ suitability for the Bundeswehr are now to be used as a basis for further testing.

The development of further colors for an even larger operational spectrum, an evaluation of the effects of surface contamination as well as a long-term observation are soon to follow. The latter will serve to monitor the ageing process of the materials used. In this context, factors such as paint adhesion and corrosion protection will be examined.

Only if these criteria are also met, can the coatings be used anywhere in the world. After all, the new technologies must be able to withstand the special conditions in theaters of operation and, at best, have a positive effect on camouflage.

by Heike Westhöfer